Language

Artemis intends to pronounce the contrast between angular geometry and organic curves.

Dualism asserts that true nature emerges not through purity, but through the coexistence of opposites.

Men proverbially believe that conviction must prove itself through the ability to contest or negate differences—such that merit of ideas can be proven only when framed against something to diminish. Restricted interpretation narrows one’s sense of choice: in how one perceives, and in the significance one assigns to difference.

It seeks to unite qualities that are certain and deterministic—concrete geometries grasped through sight—with those that are fluid and adaptable, discerned by touch.

The freedom to recognize sameness not as the absence of contrast, but as its reconciliation.

Steel

The steel used in Artemis was chosen through a lot of trial and error. It’s made using Electroslag Remelting (ESR), a refining process that results in cleaner, more consistent material—something that really shows over time. It’s hardened to 55 HRC, which we’ve found to be a sweet spot: tough, reliable, and able to hold a good edge without being brittle.

It costs roughly 2.5× the cost of 440C, not because we were chasing numbers, but because we wanted something that felt right in use. The goal wasn’t to impress on paper—it was to make something that performs well, holds up under real work, and feels dependable every time you pick it up.

Edge Geometry

The bevel angle is honed to approximately 70–80 degrees. It’s not meant to slice on contact, but to separate leather fibers cleanly when struck with intention. This reduces surface drag and gives a clean cut without unnecessary tearing.

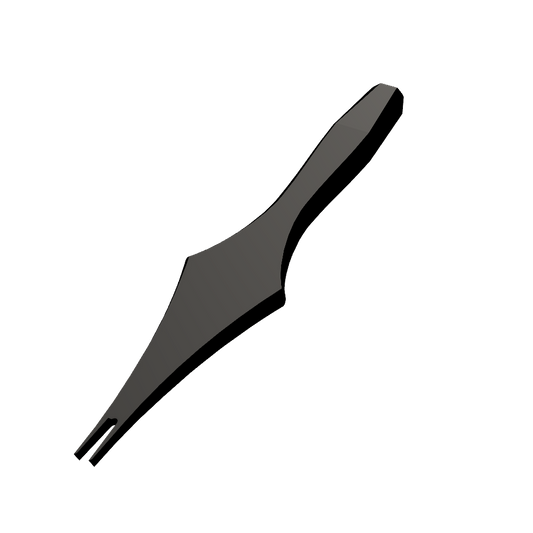

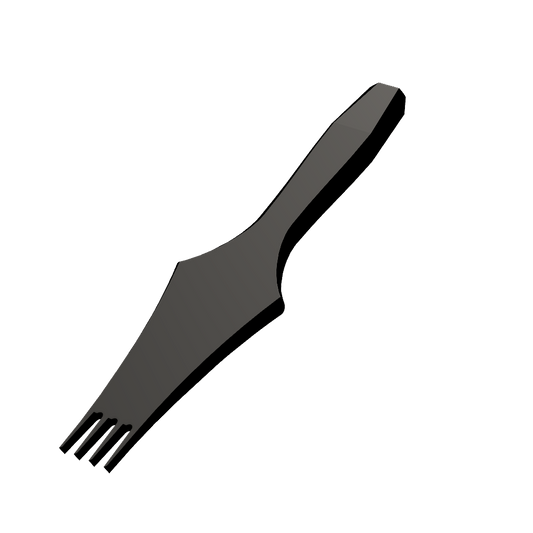

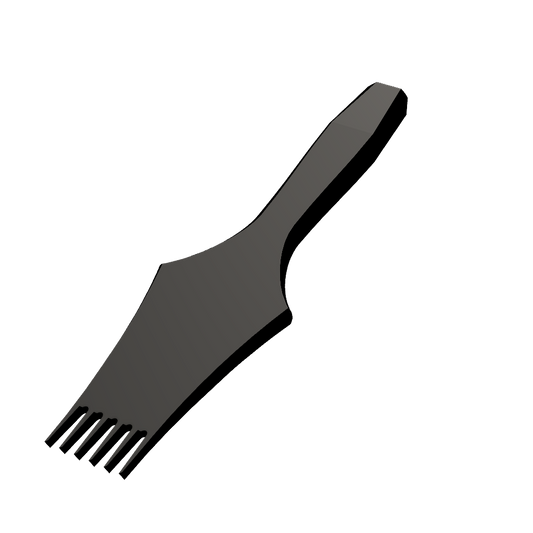

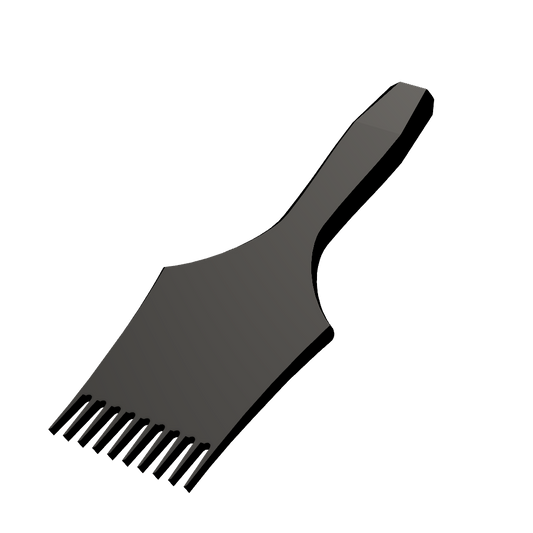

Prong Profile

The prongs are designed to be narrower than average, but also fatter. The idea is to remove as little leather fiber as possible while still opening a passage large enough for thread and needle to pass through without resistance—less trauma to the leather, better structural integrity along the stitch line.

Surface Finish

Artemis is treated with a QPQ finish (Quench-Polish-Quench), giving it a dark, matte surface. This adds corrosion resistance and provides a dry, grippy texture that’s easier to control—even with sweaty hands.

Prong Sizes & Dimensions

| Spacing Distance between prongs and stitches per inch | Bevel Width (mm) Width of the prong's beveled edge | Length (mm) Length of each prong |

|---|---|---|

| 2.00mm 13.5SPI | 1.0 | 8 |

| 2.25mm 12SPI | 1.0 | 8 |

| 2.50mm 10.8SPI | 1.1 | 8 |

| 2.70mm 10SPI | 1.2 | 10 |

| 3.00mm 9SPI | 1.3 | 10 |

| 3.38mm 8SPI | 1.4 | 10 |

| 3.85mm 7SPI | 1.5 | 10 |

| 4.00mm 6.75SPI | 1.6 | 12 |

2p - 12P Handle Length: 125 mm

20P Handle Length: 130 mm

Prong Count Availability

| Spacing | 1P | 2P | 4P | 5P | 6P | 10P | 12P | 20P |

|---|---|---|---|---|---|---|---|---|

| 2.00mm 13.5SPI |

● | ● | ● | ● | ● | |||

| 2.25mm 12SPI |

● | ● | ● | ● | ● | |||

| 2.50mm 10.8SPI |

● | ● | ● | ● | ● | |||

| 2.70mm 10SPI |

● | ● | ● | ● | ● | ● | ||

| 3.00mm 9SPI |

● | ● | ● | ● | ● | ● | ||

| 3.38mm 8SPI |

● | ● | ● | ● | ● | ● | ||

| 3.85mm 7SPI |

● | ● | ● | ● | ● | ● | ||

| 4.0mm 6.75SPI |

● | ● | ● | ● | ● | ● |

- Choosing a selection results in a full page refresh.

- Opens in a new window.